|

John Bubb |

|

|

|

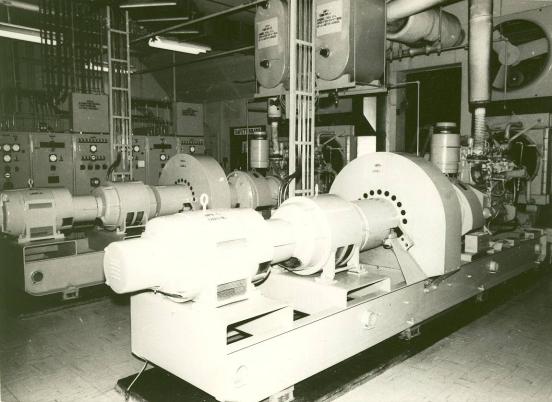

The above picture of the BMEWS No Break Generators and control panels was taken by Ivar Balsom and is used with his permission. Two power lines were run on the ground for 5 miles from the upper camp power plant. Each power line supplied an electric motor which drove a generator (alternator) which in turn supplied power to exactly half of the equipment in the building. On the same shaft as the motor and generator was a large flywheel and an electromagnetic clutch. On the other side of the clutch was a diesel engine, ready to run if power failed. When power failed the electromagnetic clutch would let-go and the inertia of the flywheel would keep the generator shaft turning and, at the same time, wind up and thus start the diesel engine. Each week our diesel technician would test the no-break generators. It was always an exciting, somewhat stressful, time with lots of noise and sometimes multiple alarms due to a brief dip in voltage. If one of the no-break generators failed, the communications link would still be maintained. In each direction (North and South) each no-break generator served one of the transmitter, exciter and heat exchanger combinations and two receivers (each receiver being tuned to one of the two remote site transmitters). In order for the communications link to fail, at least two pieces of equipment had to be out of action and sometimes more than two. Preventive maintenance was carefully scheduled between sites so as to further reduce the risk of failure (for example, transmitter maintenance at Saglek would never be performed at the same time as receiver maintenance at Hopedale). |

No-Break Motor Generator Sets (NBG - Red Boxes) |